Extensive

statistical analysis of the variability of concrete rebound hardness based on a

large database of 60 years experience

Paper published in Construction and Building Materials 53 (2014) 333-347

Authors: Katalin Szilágyi PhD, Adorján Borosnyói PhD, István Zsigovics PhD

Keywords: Concrete, non-destructive testing, rebound

index, repeatability, statistical characteristics

Abstract: Non-destructive

testing methods for concrete structures require statistical validation of reliability

model parameters. Present paper studies a comprehensive database of several

thousand test locations for the better understanding of the statistical characteristics

of rebound hardness of concrete and highlights that several gaps are found both

in current technical literature and standardisation. Detailed evaluation is

provided on repeatability and influencing parameters. Results of statistical

analyses are presented for the within-test standard deviation, coefficient of

variation, range and studentized range of rebound indices. Indications for the

reconsideration of particular statements in the technical literature and

standards are given.

1. Introduction

During the

design of reinforced concrete structures the designer specifies the strength

class of concrete that is taken into account. The same is carried out if the

performance of the concrete is determined by in-situ testing, e.g. surface

hardness testing for strength assessment. The designer’s assumption should

recognise the variability of concrete as a structural material and the designer

specifies the design strength of the concrete using its characteristic

compressive strength that covers the variability of the strength of concrete [1].

The characteristic strength is based on statistical concepts and usually means

a limit value of strength below which no more than 5% falls from test results of

a chosen concrete mix or a structure. This concept is illustrated in Fig. 1a

which sketches a histogram of concrete strengths that can correspond to a

particular series of tests and how the test results could be approximated by

e.g a normal distribution density function. Fig. 1b shows the idealized normal

distribution density function that is usually assumed in design and in quality

control based on statistical methods. The lower limit indicated in the diagram

is the characteristic strength (fck) below which no more than an

acceptably chosen part of the strength tests values shall fall. The

characteristic strength is usually given as a function of the mean strength,

the standard deviation of the strength and an appropriate margin parameter that

covers the type of the probability distribution of strength (that is not

necessarily always normal distribution), the level of the percentile (that is

not necessarily always 5%) and the reliability of the strength approximation

(that is depending on the available number of test results) in the following

form: fck = fcm – k×s; where fcm = mean

strength, k = margin parameter and s = standard deviation of strength. The same

can be formulated if one introduces the coefficient of variation for the

strength as: fck = fcm×(1– k×V); where V = coefficient of

variation for the strength and the further parameters are the same as before.

Fig. 1.

a ) Frequency histogram

of concrete strength with the best fit probability density function

Fig. 1. b) Idealized

normal probability

density function of concrete strength

Reliability

analysis techniques mostly concentrate on the use of the coefficient of

variation for taking into account the variability of different material characteristics,

rather than the standard deviation. Whether the standard deviation or the

coefficient of variation is the appropriate measure of dispersion for concrete

strength depends on which of the two measures is more nearly constant over the

range of the strength [2]. Technical literature indicates that the coefficient

of variation is considered to be more applicable for within-test evaluations [2],

however, the standard deviation remains reasonably constant over a wide range

of strengths [3]. Fig. 2 illustrates the standard deviation and the coefficient

of variation of concrete strength having the average compressive strengths in

the range of 20 to 70 MPa, based on literature data [4].

Fig. 2. a ) Standard deviation of the compressive strength of concrete [4]

Fig. 2. b) Coefficient of variation of the compressive strength of concrete

[4]

If the quality

control is good during concreting, then the probability density function (PDF)

of strength is expected to follow the normal distribution and the test results

tend to cluster near to the average strength; the histogram of Fig. 1a

is expected to be mesokurtic or leptokurtic (see Appendix for interpretation). The average strength and the mean

strength coincides for normal distribution. If the test results are not

symmetrical about the mean (i.e. skewness

exists) then a statistical analysis that presumes normal distribution is

misleading. The statistical analysis is the simplest if normal distribution for

the strength is acceptable, as the normal distribution can be fully described

mathematically by two statistical parameters: the mean strength and the standard

deviation of the strength.

A sufficient

number of tests is needed to accurately find the variation in concrete strength

and to be able to use statistical procedures for interpreting the test results [5].

If only a small number of test results is available, the estimates of the

standard deviation and the coefficient of variation become less reliable [6].

The magnitude of

the variation in the strength of concrete in the structure is a result of

quality control (over the concrete production, the transportation, the

compacting and curing procedures, the specimen preparation and the laboratory

testing of the specimens) [7, 8]. For existing structures, another source of

variability is the influence of the environment, which may be uneven on the

structure. However, for a selected set of constituent materials, the strength of

concrete is basically governed by the water-cement (w/c) ratio. Further influencing

parameters can be applied in more detailed analyses [9, 10].

Surface hardness

test of concrete is typically performed in-situ on structural concrete members.

The most important characteristic of the test is that the near-surface properties

of the concrete in a structure are directly measured. It is not common in usual

practice that parallel hardness tests are performed on moulded specimens as

well, which are made from the concrete used in the structure; it can be the

case only for pilot projects or research. For material research and device

development the most common situation is, however, the exclusive use of moulded

specimens tested under strictly controlled laboratory conditions.

During in-situ

testing, the most significant characteristic of the non-destructive tests is

that the compressive strength of the concrete is not measured in the structure.

Instead, some other related properties are measured that are correlated to the compressive

strength. It should be mentioned here that no scientific consensus exists for

the term ‘hardness’ even for the definition of the word [11]. Also,

specifically for the rebound hammer test, the possible relationship between concrete

strength and hardness (both are time dependent properties) was only recently

revealed, answering a 60 years old open question [12].

It is

demonstrated in the technical literature that the average rebound index Rm(t) and the average compressive strength of concrete fcm(t) – both are time dependent material

properties – can not be directly correlated to each other as univariate

functions; the relationship needs the introduction of the series of

multivariate functions, where the independent variables are the degree of

hydration, the type and amount of cement and aggregate, the environmental

conditions and the testing conditions. The simplest construction of the series

of the functions is introduced by the authors of present paper [12], where two

independent variables were defined for the degree of hydration in terms of the

water-cement ratio and time, and all the other influencing parameters were

taken into account by empirical constants. The model was demonstrated to be a

robust tool for the modelling of the rebound index Rm(t) vs.

average compressive strength fcm(t)

relationship [13]. It was also demonstrated that the technical literature

provided a wide range of rebound index vs. compressive strength relationships

in the last 60 years that may generate concerns of the strength estimation.

Based exclusively on the published literature data, one may erroneously

estimate the concrete strength at certain rebound indices by a ±40-60 N/mm2

variation. Results clearly demonstrated that the validity of particular

proposals should be restricted to the testing conditions and the extension of

the validity to different types of concretes or testing circumstances is

impossible [14].

The uncertainty

of the estimated compressive strength depends both on the variability of the

in-situ measurements and the uncertainty of the relationship between hardness

and strength. One must account for three primary sources of uncertainty for the

estimate of the compressive strength of concrete by surface hardness test

method [15]: 1) the uncertainty of the surface hardness test results; 2) the uncertainty

of the relationship between concrete strength and the measure of surface

hardness; 3) the variability of the concrete strength in the structure. The

first source of uncertainty is associated with the inherent variability

(repeatability) of the test method. The present paper provides information mostly

to this topic. It should be emphasized that throughout the paper, the term

repeatability and the illustrated standard deviation and coefficient of

variation results are always indicating the variability of rebound indices at a

test location and not the variability of averaged rebound indices at different

test locations. Batch-to-batch variability and spatial variability analyses are

outside the scope of the paper.

2. Significance of the study

The paper

focuses on the statistical characteristics of different surface hardness test

parameters that can be obtained by rebound hammer testing. The discussions

cover both literature and own measurement data by Schmidt rebound hammer tests.

The extensive statistical analysis of the variability of concrete rebound

hardness parameters is made by a large database of 60 years laboratory and

in-situ experience. The study covers several thousands of test locations

providing more than eighty thousand individual rebound index readings that made

possible to carry out detailed statistical analyses. It is demonstrated that

several gaps are found both in current technical literature and

standardisation. The paper intends to provide general and comprehensive data for

the better understanding of the statistical characteristics of surface hardness

of concrete. The reader can find the details of the devices and the historical

review of their development as well as the most recent theoretical

considerations in the technical literature and in selected papers of the

authors [16-21].

The accuracy of

statistical information is the degree to which the information correctly

describes the phenomena that is intended to be measured [22]. It is usually

characterized in terms of error in statistical estimates and is traditionally composed

by bias (systematic error) and variance (random error)

components. In statistics, sampling bias/sampling error is a deviated

sampling during which sample is collected in such a way that some members of

the population are less likely to be included than others. Problems with sampling

are expected when data collection is entrusted to subjective judgement of human

[22]. A biased sample causes problems because any statistical analysis based on

that sample has the potential to be consistently erroneous. The bias can lead

to an over- or underrepresentation of the corresponding parameter in the

population. In statistics, inherent bias is a bias which is due to the

nature of the situation and cannot, for example, be removed by increasing the

sample size [22]. An example of inherent bias is the systematic error of an

observer.

Systematic errors can lead to significant

difference of the observed mean value from the true mean value of

the measured attribute. Systematic errors are very difficult to deal with,

because their effects are only observable if they can be removed. Such errors

cannot, however, be removed by repeated measurements or averaging large numbers

of results. A simple method to avoid systematic errors is the correct

calibration: the use of the calibration anvil for the rebound hammers.

Random errors lead to inconsistent data. They

have zero expected value (scattered about the true value) and tend to have zero

arithmetic mean when a measurement is repeated. Random errors can be attributed

either to the testing device or to the operator.

Fig. 3. Scale of the rebound hammer

The observational

error in the case of the rebound hammer

test is due to the design of the scale of the device (Fig. 3). Its

speciality is that no odd values are indicated on the scale. Therefore, the

observer should decide during reading how the rounding of the read value is to

be carried out. As the repetition of the readings is very fast in a practical

situation, it is expected that the observer adds an inherent observational

error to the readings of the rebound

index, in favour of the even numbers. The existence of the phenomena was earlier

indicated in particular publications for natural stones [23] and concrete [24] but was not analysed thoroughly.

To see the

magnitude and the influence of such an observational error on the reading of

the rebound index, a comprehensive data survey was carried out. A total number

of 45650 rebound index readings was collected from 28 different sources. The

data are based on both laboratory research and in-situ measurements. The

rebound hammers were N-type original Schmidt hammers in all cases. The data are

provided either by technical literature or from the data archives of the accredited

testing laboratory of the BME Department of Construction Materials and

Engineering Geology. This latter group of data is confidential for the

protection of the buyers of the accredited testing laboratory, therefore,

details of the structures or the concrete mixes used for particular measurements

are not given in this paper.

Total readings,

N

|

Neven

|

Nodd

|

Relative error,

(Neven–Nodd)/N, %

|

Source of data

|

|

1

|

2160

|

1088

|

1072

|

+0.74%

|

laboratory

|

2

|

270

|

133

|

137

|

–1.48%

|

laboratory

|

3

|

120

|

62

|

58

|

+3.33%

|

in-situ

|

4

|

120

|

63

|

57

|

+5.0%

|

in-situ

|

5

|

1179

|

621

|

558

|

+5.34%

|

laboratory

|

6

|

1120

|

603

|

517

|

+7.68%

|

in-situ

|

7

|

7640

|

4189

|

3451

|

+9.66%

|

laboratory

|

8

|

510

|

284

|

226

|

+11.37%

|

in-situ

|

9

|

140

|

62

|

78

|

–11.43%

|

in-situ

|

10

|

1000

|

561

|

439

|

+12.20%

|

in-situ

|

11

|

2880

|

1623

|

1257

|

+12.71%

|

laboratory

|

12

|

5310

|

2999

|

2311

|

+12.96%

|

in-situ

|

13

|

200

|

113

|

87

|

+13.00%

|

in-situ

|

14

|

200

|

113

|

87

|

+13.00%

|

in-situ

|

15

|

3760

|

2151

|

1609

|

+14.41%

|

laboratory

|

16

|

990

|

570

|

420

|

+15.15%

|

in-situ

|

17

|

7560

|

4380

|

3180

|

+15.87%

|

laboratory

|

18

|

800

|

464

|

336

|

+16.00%

|

laboratory

|

19

|

70

|

41

|

29

|

+17.14%

|

in-situ

|

20

|

451

|

183

|

268

|

–18.85%

|

in-situ

|

21

|

460

|

276

|

184

|

+20.00%

|

in-situ

|

22

|

1070

|

644

|

426

|

+20.37%

|

laboratory

|

23

|

210

|

129

|

81

|

+22.86%

|

in-situ

|

24

|

1440

|

905

|

535

|

+25.69%

|

laboratory

|

25

|

2980

|

1873

|

1107

|

+25.70%

|

laboratory

|

26

|

1670

|

1102

|

568

|

+31.98%

|

laboratory

|

27

|

250

|

84

|

166

|

–32.80%

|

in-situ

|

28

|

1140

|

880

|

260

|

+54.39%

|

laboratory

|

Table 1.

Statistical characteristics of the rebound index

data: number of even or odd number readings and their relative error.

Table 1 summarizes the statistical characteristics of the rebound index data

in terms of counting the even and odd number readings. It can be realized that

the observational error may be significant. Over the complete field of the

45650 data points one can find 57.3% probability of even number readings and

42.7% probability of odd number readings. It should be noted here that the

45650 data points are the product of several different operators, therefore, no

general statement can be taken about operator precision or measurement

uncertainty. The unbiasedness of the data collection is highly dependent on the

operator. It can be realized (without referring to the exact sources of the

data) that the worst cases were corresponded to situations when

unskilled/untrained users performed the tests (e.g. students with lack of long term

practice in the use of rebound hammers). On the other hand, the best results

were always corresponded to laboratory research or in-situ measurements

performed by the skilled staff of the accredited testing laboratory of the BME

Department of Construction Materials and Engineering Geology or by the staff of

its predecessor institute (BME Department of Construction Materials).

From the practical point of view of material

testing – and not from that of the requirements of analytical accuracy of

probability theory – one may ask that how much is the influence of the observational error on the

reliability of concrete strength estimation based on the rebound hammer test,

as it is the most important aim in most of the cases when the rebound hammers

are used. Strength estimation usually means the estimation of the mean

compressive strength based on the mean rebound index (mean can indicate

here either the average or the median value of the rebound index) and random

errors are usually expected to have an influence on kurtosis rather than on the

mean value.

The mostly erroneous

dataset listed in Table 1 at the 28th position is selected

for the demonstration of an unfavourable performance. The dataset can be found

in the technical literature (for the right of privacy of the original authors

no reference is given here as the example is inferior). The test results were actually

collected for a diploma thesis and the operator was the candidate undergraduate

student (not at BME). The 1140 rebound index readings are the result of a test

series conducted on 5 different concrete mixes where 20 replicate readings were

recorded at 57 individual measuring locations. The overall statistical

parameters of the strength measurements for the 5 mixes are as follows (in the

order of fcm, MPa; s, MPa; V, %): mix 1) 45.8 MPa; 7.48 MPa;

16.3%, mix 2) 48.3 MPa; 8.81 MPa; 18.3%, mix 3) 46.9 MPa; 1.03

MPa; 2.2%, mix 4) 34.3 MPa; 1.73 MPa; 5.1%, mix 5) 29.4 MPa; 2.38

MPa; 8.1%, that indicates a low level of quality control during the tests (compare

to Fig. 2). The overall range is Rmin

= 20 and Rmax = 51, for

the rebound index readings. The resulted range of 31 shall not be criticised,

as these readings are not of the same concrete. The average of the 880 even

readings is Rm,even =

32.38 and the standard deviation of the 880 even readings is sRm,even

= 3.80. The average of the 260 odd readings is Rm,odd = 32.18 and the standard deviation of the 260 odd

readings is sRm,odd = 4.42. On the first look, these differences can

be considered to be negligible. If one takes a look at a more detailed

statistical parameter check then more reliable decisions can be taken. The reader

can refer first to Fig. 4 where the 57 individual measuring locations

are illustrated as Rm–fcm

(Fig. 4.a), as Rm–sR

(Fig. 4.b), and as Rm–VR

(Fig. 4.c) responses.

Fig. 4. a) Relationship between average rebound index and average

compressive strength

Fig. 4. b) Relationship between average rebound index and within-test

standard deviation

Fig. 4. c) Relationship between average rebound index and within-test

coefficient of variation of 57 individual test locations

It can be realized that the dataset indeed covers values

that confirm the above statement about the low level of quality control (the

reader can compare Fig. 4.b and Fig 4.c with Fig. 11.a and

Fig. 11.b). Further statistical considerations are illustrated in Fig.

5. The rebound index ranges of individual measuring locations are shown in Fig.

5.a, indicating with black tone the locations where the limit of 12 units

suggested by ASTM C 805 is violated. The observational error is given in Fig.

5.b, which diagram shows the differences (in percents) between the

only-even-number and only-odd-number averages calculated to each location. The

deviation has a positive sign if the only-even-number average is higher and has

a negative sign if the only-odd-number average is higher. It can be seen that

the error can reach the magnitude of 20% at specific locations. Also, there are

locations where zero number of odd readings was recorded and therefore the

error is 100%.The diagram indicates these locations with a striped tone. It can

be realized by the comparison of the two diagrams that the observational error

and the inherent variance of concrete hardness are independent parameters,

therefore, they can be separated and determined individually in theoretical

analyses.

Fig. 5. a) Range of rebound index of

57 individual test locations

Fig. 5. b) Specific observational

error of 57 individual test locations

It can be

summarized as a conclusion that the observational error can be considerable in

particular cases, but this error seems to have negligible influence when

rebound indices are averaged. At the present stage of the research, it is not

yet demonstrated if the observational error may result bias of the rebound

index data. Future statistical analyses are needed to make clear the real

influences. It is suggested, however, that a simple development of the testing

device may eliminate the operator observational error: a scale of the index

rider would be needed that indicates both even and odd values rather than only

even values as it is the case for the original design. The currently available

experimental results also demonstrate that the digital data collection of the

coefficient of restitution (see e.g. the Silver-Schmidt hammer) instead of the

operator’s eye sensory reading at the conventional rebound index (see e.g. the

original Schmidt hammer) do not improve

the precision of the measurement [25]. On the contrary: it has been shown on 10

different natural stones that the necessary sample size to arrive at the same confidence

level of the estimation of the sample mean is considerably higher for the

Silver-Schmidt hammer than is needed for the original Schmidt hammer,

regardless the magnitude of the operator observational error [25]. It calls the

attention to further future analyses before a proper possible improving

development of the original Schmidt hammers; which devices are far the most successful

non-destructive testing tools for the in-situ surface hardness testing of

concrete as well as of natural stones.

4. Normality tests for the rebound hammer

test

In mathematical

statistics, normality tests are used to determine whether a data set can be

modelled by normal distribution or not. The importance of the normality tests

concerning the rebound hammer test can be understood since normality is an

underlying assumption of many statistical procedures. There are about 40

normality tests available in the technical literature [26], however, the most

common normality test procedures of statistical analyses are the Shapiro-Wilk test, the Kolmogorov-Smirnov test, the Anderson-Darling test and the Lilliefors test. It is demonstrated in

the technical literature that the Shapiro-Wilk test is the most powerful

normality test from the above four [27]. Present chapter focuses on statistical

analyses based on the Shapiro-Wilk normality test.

Considering the

rebound hammer test, one can assume that the rebound index reading sets of separate

test locations are independent and identically distributed (i.i.d.) random

variables since it can be supposed that the probability distribution of the

rebound index does not change by location within the same concrete structure and

the separate test locations can be considered to be mutually independent. Based

on these assumptions, the central limit theorem applies for the rebound hammer

test; i.e. the probability distribution of the sum (or average) of the rebound

index reading sets of separate test locations (each with finite mean and finite

variance) approaches a normal distribution if sufficiently large number of the

i.i.d. random variables is available.

To see if the

probability distribution of the rebound index reading set of an individual test

location can be described by normal distribution or not, the Shapiro-Wilk

normality test can be run. From 24 different sources, 4555 test locations were

selected (from which 3447 of laboratory testing and 1108 of in-situ testing)

where 10 individual rebound index readings were recorded at each location by

N-type original Schmidt rebound hammer. The Shapiro-Wilk test was run to all

data sets and the values for the W statistic was found to be in a wide range of

Wmin = 0.510 (p → 0) to Wmax = 0.988 (p > 0.99) with a

mean value of Wm = 0.885 (p = 0.145). Values of the W statistic

follow a Beta probability distribution with strong negative skewness. It can be

basically concluded that the hypothesis of normality can be accepted at very

low levels of probabilities for individual test locations. From the

analysis it can be realized that the hypothesis of normality can be accepted at

50% or lower probability in 87% of the cases. In 10% and 5% of the cases the

hypothesis of normality can be accepted at 64% and 80% probability,

respectively. The hypothesis of normality can be accepted at 95% or higher

probability only in less than 2% of the cases.

It is not the

aim of the authors to suggest if a triangular or a rectangular (uniform) probability

distribution could be a better estimate for the rebound index reading set of an

individual test location; future research is needed.

The practical

application of the central limit theorem for the rebound index reading sets of

individual test locations, however, may be a good indicator of the precision of

the rebound hammer test. Two comparisons have been made in this sense. During

the first one, literature data was analysed in which 36 individual, identical

concrete cubes of 150 mm

were tested by N-type original Schmidt hammer (with average compressive

strength of fcm = 29.6 MPa); recording 10 rebound indices on each

cube [28]. Test results are considered to be rather accurate with an average

rebound index of Rm = 36.9,

with a standard deviation of the rebound index of sR = 2.2 and a

coefficient of variation of the rebound index of VR = 5.9%. The practical

application of the central limit theorem was the running of the Shapiro-Wilk

test for 1, 2, 3, …, 36 rebound index reading sets combined. The expected

behaviour is the value of the W statistic approaching unity by the increasing

number of test locations combined. Fig. 6

summarizes the values of the W statistic as a function of increasing number of

specimens included in the analysis. The value of the W statistic is approaching

unity very fast, as it was expected.

Fig. 6. W statistic of rebound index as a function of increasing

number of specimens

During the

second comparison, four different rebound indices were compared by the

laboratory testing of 11 individual, identical concrete cubes of 150 mm (with average

compressive strength of fcm = 64.7 MPa). The testing devices were an

L-type original Schmidt hammer, an N-type original Schmidt hammer and a first

generation Silver-Schmidt hammer capable to record both R-values (conventional

rebound index) and Q-values (square of the coefficient of restitution) (it

should be noted here that the recently available second generation Silver-Schmidt

hammers are no more capable to record the R-values). Table 2 summarizes test results. 20 rebound index recordings were

taken by each device on each specimen. It can be seen that the highest

precision corresponds to the N-type original Schmidt hammer (highest precision

means here the lowest range and the lowest standard deviation for the measured

values at individual test locations). Lower precision of the L-type original

Schmidt hammer and of the Silver-Schmidt hammer is due to the lighter hammer

masses impacting within both devices and the sensitivity of the electro-optical

recording (Silver-Schmidt hammer).

Table 2.

Statistical

characteristics of rebound indices obtained by different types of rebound

hammers.

Fig. 7. W statistic of rebound index provided by different rebound

hammers as a function of increasing number of specimens

The Shapiro-Wilk

test was run in a similar way as of the first comparison. Fig. 7 summarizes the values of the W statistic as a function of

increasing number of specimens combined. One can realize that values of W

statistic approaches the fastest to unity for the N-type original Schmidt

hammer due to its superior precision. In the case of the L-type original

Schmidt hammer tendencies are similar, but the W statistic has lower values. Results

are controversial in the case of the Silver-Schmidt hammer. Tendency of the

values for the W statistic seem to decrease rather than increase, which

contradicts probability theory and apparently indicates that the central limit

theorem does not apply. The observed behaviour highlights the disadvantages of

the electro-optical data collection. The results confirm the long term

advantageous experiences with the N-type original Schmidt hammers (see e.g. [25]

as well) and further appreciate – after more than 60 years – the original

robust design of the device that provides superior precision compared to its

competitors in use today.

5. Current standardisation of the

rebound hammer test

Non-destructive

testing methods for concrete structures require the statistical validation of

the model parameters. In particular cases the formulation of the model is

directly related to the statistical characteristics of the parameters

considered. Laboratory and in-situ experiences have demonstrated that several

material characteristics which are connected to the degree of hydration of

hardened cement paste as well as of hardened concrete (i.e. modulus of

elasticity, tensile and compressive strengths and surface hardness properties)

may be modelled as random variables of normal probability distribution. There

are, however, material properties for which the validity of the assumption of

normal distribution can not be demonstrated or even no any indication is found

in the technical literature considering an appropriate probability

distribution. Numerical modelling or numerical simulations of concrete hardness

behaviour need acceptable simplifications of the real behaviour. The current

state of the standardisation of the rebound hammer test is summarized briefly

in present chapter to be able to find the gaps in present knowledge and to

provide a basis for the literature survey and a comprehensive analysis of the

statistical characteristics of the rebound hammer test parameters given in

further chapters of the paper.

The ISO 1920-7

International Standard and the EN 12504-2 European Standard specifies the

method for determining the rebound index and the EN 13791 European Standard

summarises guidance for the assessment of the in-situ concrete compressive

strength in structures [29-31]. It is generally stated that the rebound hammer

test of concrete is not intended to be an alternative to the compressive

strength testing, but with suitable correlation, it can provide an estimate of

the in-situ strength. Therefore, it can be supposed that the rebound hammer

tests may provide alternative to drilled core tests for assessing the

compressive strength of concrete in a structure if core test results can be

obtained in limited number. Two different strength assessment procedures are

described in EN 13791; both by the formulation of specific relationships

between the in-situ compressive strength and the rebound indices. One

alternative suggests the establishment of a relationship based on at least 18

drilled core strength results, while the other suggests the use of a basic

curve, together with a shift of the basic curve, established by means of at

least 9 drilled core strength results detailed in the standard. It is claimed

that the basic curve has been set at an artificially low position so that the

shift is always positive. The basic curve for the in-situ concrete compressive

strength (fc,is) is a bilinear relationship, fc,is =

1.25×R – 23 (20 ≤ R ≤ 24) and fc,is = 1.73×R – 34.5 (24 ≤ R ≤ 50), where R is the median value of the rebound index (acc.

to EN 12504-2). Strength estimation without the direct calibration to drilled

core strength results is not supported by the basic text of EN 13791.

National Annex

of DIN EN 13791 suggests in its Table NA.2 numerical values according to which

the rebound hammer method may be used singly under restricted conditions and

the strength assessment can be performed by the suggested values [32]. The general

idea is attributed to Manns and Zeus [33] and was adopted by CEN/TC 104/SC1 as

well [34]. The suggested values are summarised in Table 3.

The ASTM C 805

International Standard contains precision statements for the rebound index of

the rebound hammers [35]. It is given for the precision that the within-test

standard deviation of the rebound index is 2.5 units, as “single-specimen,

single-operator, machine, day standard deviation”. Therefore, the range of ten

readings should not exceed 12 units (taking into account a k = 4.5 multiplier

given in ASTM C 670). Dependence of the within-test standard deviation on the

average rebound index is not indicated. Particular literature data support the

ASTM C 805 suggestions, e.g. [36].

For the bias of

the rebound hammer test no evaluation is given in the ASTM C 805 standard [35].

It is indicated that the rebound index can only be determined in terms of this

test method, therefore, the bias can not be evaluated. This statement, however,

in the point of view of the authors of present paper should be restricted to

the Digi-Schmidt and the Silver-Schmidt type rebound hammers as only these

models provide the rebound index readings digitally. The original Schmidt

hammers have a sliding marker for the indication of the rebound index that

shows the measured value over a scale on which only even numbers are indicated.

The operator decides the reading based on his own judgement whether the reading

is an odd or an even number. This sampling does not, therefore, exclude the

possibility of existence of an observer error or an observer bias.

American

Concrete Institute Committee 228 reapproved in 2003 the ACI 228.1R-03 Committee

Report that covered implications on the statistical characteristics of the

rebound hammer test; as an extension of ACI 228.1R-89 [15, 37]. No update has

been made since then up today. The Report illustrated – on a basis of three

literature references from the 1980’s – that the within-test standard deviation

of the rebound index shows an increasing tendency with increasing average and

the within-test coefficient of variation has an apparently constant value of

about 10% (Fig. 8). Particular literature data contradicted the

findings, e.g. [38]. The reader can realize that the information given in Fig.

8 is rather limited as well as apparently contradicts to an expected

behaviour that can be postulated to be a similar trend that was shown in Fig.

2 for concrete strength. Number of data points indicated in Fig. 8

is only 55 and the range of the analysed rebound index is narrow and restricted

to low values; all fall below rebound index of 35.

It can be

realized that still several gaps can be found in the recommendations in terms

of either limitations of the proposed methods or the missing statistical

verification of the indicated numerical values. In the next chapters, these

open questions are analysed without the aim of providing a complete solution

for the topics discussed.

Fig. 8. a) Within-test standard deviation of rebound index [15]

Fig. 8. b) Within-test coefficient of variation of rebound index [15]

Fig. 8. a) Within-test standard deviation of rebound index [15]

Fig. 8. b) Within-test coefficient of variation of rebound index [15]

6. Statistical analyses of test parameters in view of

current standardisation

6.1 Limitations for the use of basic curve of EN 13791

The idea of EN

13791 with the calibration of the rebound hammer tests to drilled core strength

tests is a practical and undeniable method to overcome the concerns of strength

assessment, however, it eliminates the advantages of the non-destructive method

and technically turns back to the destructive testing. The main driver of the

calibration is the relationship between the rebound index and the in-situ

compressive strength obtained by drilled cores. It can be demonstrated that the

development of a relationship based on 18 drilled cores and the corresponding

rebound indices can result an acceptable confidence level for the strength

assessment [6]. However, the use of the basic curve suggested in EN 13791 for

the calibration by 9 drilled cores needs to be reconsidered.

Fig.9. a ) Empirical curves found in the technical literature between the

rebound index and compressive strength.

Fig. 9. b) Experimental rebound index – compressive strength results (2658 test locations) together with the basic curve given in EN 13791.

Fig.

Fig. 9. b) Experimental rebound index – compressive strength results (2658 test locations) together with the basic curve given in EN 13791.

Fig. 9.a indicates 40 empirical

curves found in the technical literature for the assessment of concrete

strength by the rebound hammer tests together with the basic curve given in EN

13791. Fig. 9.b indicates

experimental results (2658 testing locations) collected from the technical

literature and measured by the authors of present paper in the range of average

rebound indices Rm = 12.3 to 58.6 and average compressive strengths

of fcm = 6.1 MPa to 105.7 MPa, together with the basic curve given

in EN 13791. It can be realized that the basic curve is actually not set to an

artificially lowest position for which always a positive shift could be applied

for the actual strength assessment. Basic curve of EN 13791 is, therefore,

suggested to be reconsidered. It may be also added that numerical values

summarised in Table 3 according to

the National Annex of DIN EN 13791 as well as of CEN/TC 104/SC1 N 295:1998 (claimed

to be suitable for the rebound hammer test used singly for in-situ strength

assessment) are located very close to the basic curve of EN 13791, therefore,

do not always result conservative estimates either. Values given in Table 3 are suggested to be reconsidered.

Table 3.

Minimum median values of rebound indices corresponding to the strength classes [32-34].

Note: Bn and C classes indicated in the table are concrete compressive strength classification for normal weight concrete according to earlier German and recent European nomenclature, respectively.

Table 3.

Minimum median values of rebound indices corresponding to the strength classes [32-34].

Note: Bn and C classes indicated in the table are concrete compressive strength classification for normal weight concrete according to earlier German and recent European nomenclature, respectively.

In the

followings a short numerical example is presented to highlight some antagonism

hidden in the assessment methods suggested by EN 13791. Input data is taken

from the technical literature [39]. Eighteen drilled cores were tested in

compression and the corresponding average rebound index values (Rm,min

= 22.2; Rm,max = 39.1) were also published along with the

compressive strength values (fc,min = 19.0; fc,max =

41.0). Fig. 10.a. indicates the experimental results together with the

basic curve of EN 13791 as well as the 10th percentile curve that

can be obtained from the basic curve by shifting according to the method

described in EN 13791 Ch. 8.3 as Alternative 2 method [29]. If one uses

the compressive strength results of the 18 drilled cores and assesses the

strength class according to EN 13791 Ch. 7.3.2 (Approach A) then

concrete strength class of C20/25 is resulted (where fcm(n=18),is =

27.5 MPa, fc,is,lowest = 19 MPa, sis = 6.7 MPa,

therefore, fck,is = 17.6 MPa > fck,is,nom = 17 MPa).

If one, however, uses the 10th percentile curve that was obtained

from the basic curve by the shift and applies it to the actually recorded

average rebound index values (i.e. estimates the in-situ compressive strength

values by the acceptance of the 10th percentile curve and supposes

that the 18 average rebound index values are available from Schmidt hammer

tests performed on the structure without preparing any more drilled cores) then

completely different concrete strength class can be resulted: concrete strength

class of C12/15 (where fcm(n=18),is,R = 23.4 MPa, fc,is,lowest,R

= 9.2 MPa, sis,R = 7.2 MPa, therefore, fck,is,R = 12.8

MPa > fck,is,nom = 10 MPa). If one deviates from the suggestions

of EN 13791 and prepares the 50th percentile curve rather than the

10th percentile curve by shifting the basic curve and assesses the concrete

strength class then C16/20 would be resulted. It can be concluded that the

shape of the basic curve is not optimal and its use may result

over-conservative strength estimation in certain cases. Coefficient of

variation of the measured and the estimated compressive strengths may also

indicate that the strength estimation is not powerful enough for the analysed

case: Vc,is = 24.34% for the actually measured core strengths and Vc,is,R

= 30.79% for the strengths estimated by the 10th percentile curve. It

is also possible to follow the suggestions of EN 13791 Ch. 8.2 (Alternative

1) for the analysed case and establish a specific relationship between the

in-situ compressive strength and the rebound index result. For this example a

best fit power function estimate was established in the form of fc,is,R

= 0.1474×R1.521 of which regression coefficient was found to be R2

= 0.82 and the 10th percentile curve was set as shown in Fig. 10.b.

If one assesses the strength class then C16/20 is resulted (where fcm(n=18),is,R

= 23.8 MPa, fc,is,lowest,R = 12.9 MPa, sis,R = 5.7 MPa,

therefore, fck,is,R = 15.4 MPa > fck,is,nom = 14 MPa).

It can be also demonstrated that the estimation is rather powerful: coefficient

of variation for the estimated strengths becomes Vc,is,R = 23.86%

that is almost equal to the coefficient of variation of the actually measured

core strengths.

Fig.10. a ) Experimental results of drilled cores together with the basic

curve of EN 13791

Fig. 10. b) Experimental results of drilled cores together with the best fit curve

Fig.

Fig. 10. b) Experimental results of drilled cores together with the best fit curve

According to the

ISO 3534-1 International Standard the repeatability is the precision under

conditions where independent test results are obtained with the same method on

identical test items in the same laboratory by the same operator using the same

equipment within short intervals of time [40]. Reproducibility means the precision

under conditions where test results are obtained with the same method on

identical test items in different laboratories with operators using different

equipment [40]. In the nomenclature of ACI 228.1R-03 Committee Report

repeatability is referred as within-test variation and reproducibility is referred

as batch-to-batch variation [15].

An extended repeatability

analysis has been made on 8955 data-pairs of corresponding average rebound indices

and standard deviations of rebound indices that were collected from 48

different sources (in which the number of in-situ test locations was 4785 and

the number of laboratory test locations was 4170; resulting more than eighty

hundred individual rebound index readings). Range of the studied concrete

strengths was fcm = 3.3 MPa to 105.7 MPa, and the range of the individual

rebound indices was R = 10 to 63. The

data are based on both laboratory research and in-situ measurements on existing

buildings. The rebound hammers were N-type original Schmidt hammers in all cases.

The data is provided either by technical literature or from the data archives

of the accredited testing laboratory of the BME Department of Construction

Materials and Engineering Geology. The averages and the standard deviations

were calculated by 10 or 20 replicate rebound index readings on the same

surface of a concrete specimen during laboratory tests, or at the same

measuring area in the case of in-situ testing. The data were analysed to see

the general repeatability

(within-test variation) behaviour of the rebound hammer testing. Analysis of reproducibility (batch-to-batch

variation) was not the aim of the authors. The range of the analysed data is from

Rm,min = 12.2 to Rm,max = 59.0 for the

averages and from sR,min = 0.23 to sR,max = 7.80 for the standard

deviations. Coefficient of variation was also calculated and analysed. Range

was found to be as from VR,min = 0.43% to VR,max = 31.12%.

Fig. 11.a shows the graphical representation of the statistical analysis

considering the within-test variation as standard deviation over the average

rebound index, while Fig. 11.b indicates the same but considering the

within-test variation as coefficient of variation over the average rebound

index. The reader can clearly realize that these parameters have similar

tendency to that of the within-test variation of concrete strength has, as it

was introduced earlier by Fig. 2; i.e. no clear tendency is found in the

standard deviation over the average and a clear decreasing tendency can be

observed in the coefficient of variation by the increasing average. Hence the implications

given by the ACI 228.1R-03 Committee Report (Fig. 8) is suggested to be

reconsidered.

Fig.11. a ) Within-test standard

deviation over the average rebound index

Fig. 11. b) Within-test coefficient of variation over the average rebound index

Fig.

Fig. 11. b) Within-test coefficient of variation over the average rebound index

6.3 Statistical parameter analyses

connected to ASTM C 805

There are two underlying

assumptions in the precision statements of the rebound index given in the ASTM

C 805 International Standard: (1) the within-test standard deviation of the

rebound index has a constant value independently of the properties of the

actual concrete and of the actual operator error, and (2) the percentage points

of the standardized ranges of N(m,1) normal probability distribution

populations can be applied for the determination of the acceptable range of

rebound index readings at test locations. No indication is given in the ASTM C

805 either about the probability distribution of the within-test standard

deviation of the rebound index or about its percentile level for which the

value is given in the standard. In the absence of the above information one may

assume – as a first estimate – that the within-test standard deviation of the

rebound index has a normal probability distribution and

the value sR = 2.5 is its mean value.

An extended

statistical analysis has been made on the previously detailed 8955 data-pairs

of corresponding average rebound indices and standard deviations of rebound indices

that were collected from 48 different sources (in which the number of

in-situ test locations was 4785 and the number of laboratory test locations was

4170). It can be realized in Fig.

12 that the distribution of the within-test standard deviation of the rebound

index has a strong positive skewness (g = 1.7064), therefore, the assumption of the

normal probability distribution should be rejected. Fit of distributions

resulted that a three-parameter Dagum

distribution (also referred in the literature as generalized logistic-Burr or

inverse Burr distribution) gives the best goodness of fit out of more than 60

different types of distributions. The parameters of the distribution function

are: a = 1.7958, b =3.7311, c = 1.2171.

Empirical mean value of the standard deviation of the rebound index is E[sR] = 1.667; the median value is m[sR] = 1.5; the mode value is Mo[sR] = 1.45; the

95% percentile value is v95[sR] = 3.1526; for

the analysed range of sR = 0.23 to 7.80.

It can be

realized that the sR = 2.5 value does not coincide either with the

mode, or the median (= 50th percentile), or the mean value, but rather

corresponds to a p = 88.5% probability level. If one would estimate the

probability distribution with a N(1.677, 0.75) normal distribution (for which

the goodness of fit is considerably weaker than that of the Dagum distribution)

then the sR = 2.5 value would correspond to a p = 86.7% probability

level.

Fig. 12. Relative frequency histogram together with the best goodness of fit three-parameter Dagum probability density function (PDF) of the standard deviation of the rebound index (sR) corresponding to 8955 test locations

Next check can be the analysis of the rebound index ranges (rR = Rmax – Rmin) at the test locations in the case of the real measurements. Fig. 13 indicates the empirical probability histogram together with the best goodness of fit four-parameter Burr distribution corresponding to 8342 test locations (in which the number of in-situ test locations was 4785 and the number of laboratory test locations was 3557). Note that the rR analysis is based on a slightly smaller collection of data than that of the sR analysis. In the technical literature several references include only the average rebound index and the standard deviation of the rebound index without providing the individual rebound index readings. That is the reason of the difference between the sizes of the examined databases. One can again realize a strong positive skewness (g = 1.9432). The parameters of the distribution function are: a=0.89001; b=4.0809; c=3.755; d=0.41591.

Empirical mean value of the range of the rebound index is E[rR] = 4.8068; the median value is m[rR] = 4; the mode

value is Mo[rR] = 3.75; the 95% percentile value is

v95[rR] = 9; for the analysed range of rR = 1 to 24.

Considering the

value of rR = 12 as of the ASTM C 805 proposal, a p = 98.7%

probability level can be determined. The rebound index range at a test location

corresponding to the p = 95% probability level as of the ASTM C 805 target is

found to be rR = 9.

Fig. 13. Relative frequency histogram together with the best goodness of fit four-parameter Dagum probability density function (PDF) of the range of the rebound index (rR) corresponding to 8342 test locations

Fig. 13. Relative frequency histogram together with the best goodness of fit four-parameter Dagum probability density function (PDF) of the range of the rebound index (rR) corresponding to 8342 test locations

After the above

statistical analyses that are only partly confirming the assumptions of ASTM C

805, the next check can be the analysis of the assumption of ASTM C 670 that actually

suggests the application of the theory of standardized ranges (w = r/s) for N(m,1) normal

probability distribution populations for

the determination of the multiplier applied to the maximum acceptable range [41].

One may realize for the rebound hammer test (if 10 replicate readings are

considered at each test location) that the suggested value of the multiplier is

k = 4.5 according to ASTM C 670, which is the one-digit round value of the

percentage point of the standardized range (w) for a sample of n = 10

from a N(m,1) normal probability distribution population corresponding to a

cumulative probability of p = 95% (w = 4.474124; see e.g [42]). The standardized

ranges usually can not be applied for actual measurements as the real standard

deviation (s) is not known. Therefore, the studentized ranges (q = r/s) can be

introduced for N(m,s2) normal probability distribution

populations for the selection of the multiplier applied to the maximum

acceptable range. Based on the number of the measured results an appropriate

degree of freedom (n) for the independent estimate s2 of s2 should be selected. For large samples (n→∞) the percentage point of

the studentized range (q) approaches to the percentage point of the standardized range (w). Fig. 14 indicates the cumulative

distribution function of the calculated studentized ranges (qR = rR/sR) corresponding to the 8342 test

locations together with the percentage points of the standardized ranges for n

= 10 of N(m,1) for cumulative probabilities of p = 0.01 % to 99.99% (based on [42]).

It is assumed for the present analysis that the comparison of the empirical

studentized ranges (qR) with the standardized ranges (w) is acceptable

due to the large number of measured data. It can be realized that the median (=

50th percentile) values are almost equal; for the empirical values of the

studentized ranges qR = 2.991 and for the standardized

ranges by [42] w = 3.024202. It is demonstrated in the technical literature that the

probability distribution of the standardized ranges (w) has a positive skewness (g = 0.3975),

therefore the mean value E[w] does not equal to the median value, but E[w] = 3.077505 [42]. The

probability distribution of the empirical studentized ranges (qR) corresponding to the 8342 test locations, however, has a negative

skewness (g = –0.26501), and the mean value is E[qR] = 2.9794. Fit of distributions resulted that a four-parameter Pearson VI distribution (also referred

in the literature as beta prime or inverse beta distribution) gives the best

goodness of fit out of more than 60 different types of distributions. The

parameters of the distribution function are as follows:

where:

where:

in which a = 41399.0, b = 27867.0, c = 35.186, d = –49.297

Fig. 14 clearly indicates

the difference in the probability distributions of the standardized ranges (w) by [42] and

that of the empirical studentized ranges (qR) corresponding to the 8342 test locations. One can realize that the

difference is considerable at the cumulative probability level of p = 95%; i.e.

w =

4.474124 and qR = 3.635.

As the selection

of the analysed test locations was free of any filtering, it is assumed that further

increase in the number of the data points would not result better fit between

the probability distributions of the standardized ranges (w) and that of

the empirical studentized ranges (qR). Based

on the present comprehensive statistical analysis, the application of Table 1 of ASTM C 670 for the rebound hammer

test is suggested to be reconsidered.

Fig. 14. Cumulative probability distribution function (CDF) of the calculated studentized ranges (qR = rR/sR) corresponding to 8342 test locations together with the standardized ranges (w) to n = 10 of N(m,1) for cumulative probabilities of p = 0.01 % to 99.99%.

Fig. 14. Cumulative probability distribution function (CDF) of the calculated studentized ranges (qR = rR/sR) corresponding to 8342 test locations together with the standardized ranges (w) to n = 10 of N(m,1) for cumulative probabilities of p = 0.01 % to 99.99%.

7. Influences on the repeatability of

the rebound hammer test

The relatively

large number of data made possible to study the distribution of the repeatability

parameters in further details. Considering the probability density function of

the coefficient of variation of the rebound index, a strong positive skewness is

realized again (g = 2.2472). Fit of distributions resulted that a three-parameter Dagum distribution gives the best

goodness of fit out of more than 60 different types of distributions for the

coefficient of variation of the rebound index readings. The parameters of the distribution

function are: a = 2.2255, b =3.1919, c = 2.7573.

Empirical mean value of the coefficient of variation of the rebound index is E[VR] = 4.4021%; the

median value is m[VR] = 3.8%; the mode value is Mo[VR] = 3.125%; the 95% percentile value is v95[VR]

= 9.2132%; for the analysed range of VR = 0.43% to 31.12%.

The findings

confirm experimental data available for the repeatability parameters of

concrete strength [43, 44]. It was demonstrated in the literature – based on an

extensive analysis of 10788 drilled core samples taken from 1130 existing

reinforced concrete buildings – that the coefficient of variation of concrete

strength had a lognormal probability distribution with strong positive

skewness, while normal probability distribution was found for the compressive strength

itself (conventional concretes were studied with compressive strength lower

than 50 MPa; [44]). Similar observation can be made if one analyses the

distributions of the standard deviation and the coefficient of variation of

concrete strength indicated earlier in Fig. 2 in this sense (see Fig. 15).

Fig.

15. Relative

frequency histogram together with the best goodness of fit three-parameter

Dagum probability density function (PDF) of the coefficient of variation of the

rebound index (VR) corresponding to 8955 test locations

From a reliability analysis point of view one may practically select the coefficient of variation as the parameter of repeatability for the rebound hammer test. For this purpose, however, the governing parameters over the changes of the coefficient of variation are needed to be known. The authors of present paper have analysed the available database, with the selection of the following possible influencing parameters: the w/c-ratios of the concretes, the age of the concretes, the cement types used for the concretes, the testing conditions of the concretes (dry/wet), the carbonation depths of the concretes and the impact energy of the rebound hammers (N-type original Schmidt hammer with impact energy of 2.207 Nm or L-type original Schmidt hammer with impact energy of 0.735 Nm).

For the analysis

of the age of the concretes, 102 different concrete mixes were selected for

which the development of the coefficient of variation was possible to be

followed in time. The age of the tested concretes was between 1 day and 240

days. The measuring device was N-type original Schmidt hammer. All sources was

laboratory studies, no in-situ measurements were available. The behaviour was

found to be typical in each case, therefore, it was reasonable to prepare a

smeared, unified response for all the 102 concrete mixes, apart from the differences

in their compositions (Fig. 16).

Fig. 16. Coefficient of variation of the rebound index (VR) in time

The following observations can be made. In the first 14 days a rapid decrease in the coefficient of variation is measured that is attributed to the fast hydration and the drying out of the tested surfaces. A minimum is reached in the coefficient of variation at the age of 28 to 56 days. The reason is the slowing down of the rate of hydration. Over 56 days of age a gradual increase is observed in the coefficient of variation attributed to the more and more pronounced influence of carbonation. The direct relationship between the depth of carbonation and the within-test coefficient of variation of the rebound index is discussed later in present paper.

Fig. 16. Coefficient of variation of the rebound index (VR) in time

The following observations can be made. In the first 14 days a rapid decrease in the coefficient of variation is measured that is attributed to the fast hydration and the drying out of the tested surfaces. A minimum is reached in the coefficient of variation at the age of 28 to 56 days. The reason is the slowing down of the rate of hydration. Over 56 days of age a gradual increase is observed in the coefficient of variation attributed to the more and more pronounced influence of carbonation. The direct relationship between the depth of carbonation and the within-test coefficient of variation of the rebound index is discussed later in present paper.

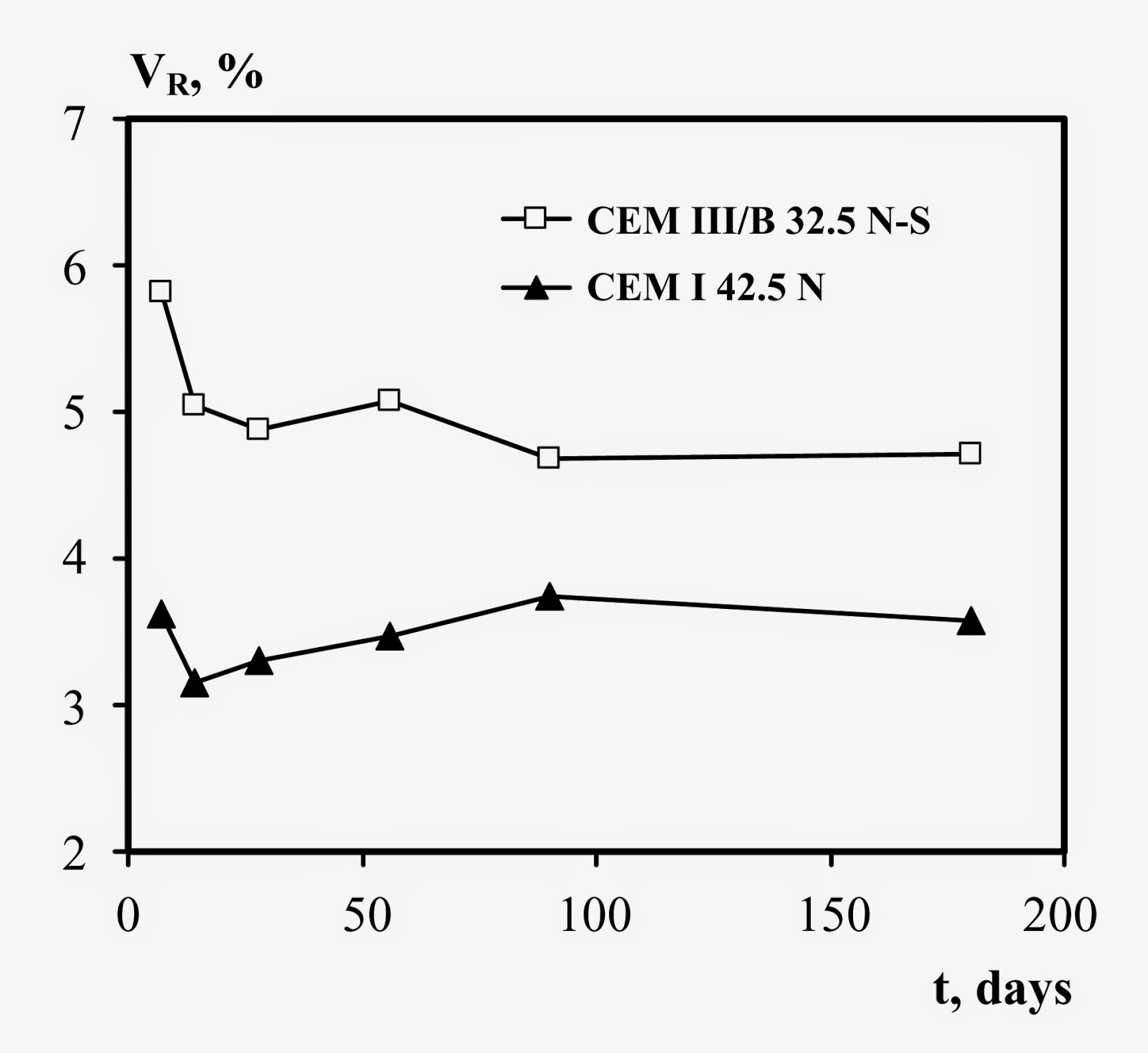

The 102 concrete

mixes selected for the above analysis made possible to analyse the influence of

the cement type on the repeatability parameters. Nine cement types were studied

(in accordance with the designations used in EN 197-1 European Standard): CEM I

32.5; CEM I 42.5 N; CEM I 42.5 N-S; CEM I 52.5; CEM II/A-S 42.5; CEM II/A-V

42.5 N; CEM II/B-M (V-L) 32.5 N; CEM III/A 32.5 N-MS; CEM III/B 32.5 N-S. The

influence of the applied cements was visible and robust (Fig. 17). It

was found experimentally that the lowest coefficient of variation can be

reached for the rebound index with the use of CEM I type Portland cements over

the studied period of time. The coefficient of variation is increasing with

decreasing the strength class of CEM I type Portland cements (not illustrated directly

in Fig. 17). The use of blended cements (CEM II) or slag cements (CEM

III) always resulted in higher coefficient of variation over the studied period

of time, when compared to reference mixes made with Portland cements (CEM I). Differentiation

between the influences of different hydraulic additives (fly ash to slag) for

the blended cements (CEM II) or between the amount of slag applied for the slag

cements (CEM III) was not possible due to the limited data available. Future

research is needed in this field.

Fig. 17. Influence of the type of cement on the coefficient of variation of rebound index (VR) in time

Fig. 17. Influence of the type of cement on the coefficient of variation of rebound index (VR) in time

The influence of

the water-cement ratio was possible to be studied for six types of cements with

the analysis of the results of 93 different concrete mixes. The range of the

studied water-cement ratios was w/c = 0.35 to w/c = 0.65. It was realized, that

the coefficient of variation of the rebound index becomes lower if the

water-cement ratio is decreased while all the other concrete technology

parameters (including compacting) is unchanged.

As it was

mentioned above, the carbonation was found to have a more pronounced influence

on the repeatability of the rebound hammer tests on mature concretes,

therefore, a targeted analysis was performed on mature concrete specimens of

which age was 2 to 5 years during testing. 30 different mixes of concretes were

selected for the analysis with the range of compressive strength of 42.6 to

91.7 MPa. The measured depths of carbonation were found to be between 2.2 mm to 22.8 mm . It was

demonstrated that the coefficient of variation of the rebound index is higher

for higher depths of carbonation (Fig. 18).

Fig. 18. Coefficient of variation of the rebound index (VR) vs. average depth of carbonation (xc)

Fig. 18. Coefficient of variation of the rebound index (VR) vs. average depth of carbonation (xc)

The authors of

present paper have found during their earlier in-situ testing experiences on

masonry structures that the within-test standard deviation and the within-test coefficient

of variation of the rebound index is very sensitive to the impact energy,

therefore, a comparative study was performed on concretes using L-type and

N-type original Schmidt hammers to reveal the existence of this influence for

concretes as well. CEM 42.5 N type cement was selected and w/c = 0.40 – 0.50 –

0.65 water-cement ratios were applied for the same aggregate mix. In the

concretes both the cement paste content and the consistency was set to be

constant. The age of the test specimens was 3 to 240 days. It was demonstrated

that both the standard deviation and the coefficient of variation of the

rebound index is very sensitive to the applied impact energy before the age of

90 days. Experiments showed that the differences become more balanced and seem

to disappear at ages over 90 days (Fig. 19).

Fig.19. a ) Effect of the w/c ratio and the impact energy on the coefficient

of variation of the rebound index in time, L-type original Schmidt hammer

Fig.

Fig. 19. b) Effect of the w/c ratio and the impact energy on the coefficient

of variation of the rebound index in time, N-type original Schmidt hammer

8. Repeatability condition check according to EN

12390-3

There is

considerable interest, from a practical point of view, on a possible connection

of the repeatability of in-situ measurements (e.g. the rebound hammer tests)

and that of the compressive strength tests: namely, it is an open question if

the coefficient of variation of the rebound index (VR) could be an

acceptable estimate of the coefficient of variation of concrete compressive

strength (Vf). Reliability analyses need the value of Vf,

however, it is time consuming and expensive to establish its value in a

practical situation. Rebound hammer test, on the other hand, is easy to perform

and may provide a far less time consuming and expensive solution in a practical

situation. Present chapter, therefore, illustrates own results in this field.

Laboratory tests

were performed on 1350 concrete cubes of standard geometry on a wide range of

water-cement ratios (w/c = 0.35 to 0.65) using nine different cement types

detailed earlier in present paper. Rebound hammer tests according to [30] and

compressive strength tests according to [45] were performed on two cubes of the

same mix at the age of 1, 3, 7, 14, 28, 56, 90 and 180 days of age. The

repeatability of the strength tests was calculated according to EN 12390-3 as

the normalized range in percents: rf = (fc,max

– fc,min)/fcm×100. Similarly, the normalized ranges in

percents corresponding to the rebound hammer test results were formulated as: rR = (Rm,max – Rm,min)/Rm,avg×100,

where Rm,i is the average rebound index corresponding to each cubes

and Rm,avg is the average of Rm,max and Rm,min.

The EN 12390-3

standard indicates that the precision of compressive strength testing (i.e. the

repeatability of compressive strengths obtained on 150 mm cubes) is acceptable

if rf ≤ 9%. Regarding present tests, the

value of rf was found to be lower than 9% in

95.3% of the cases, with a mean of E[rf] = 3.75% and

a median of m[rf] = 2.71% so the tests can be

considered to be rather precise. No considerable

influence of the age of concrete at testing was observed.

Fig. 20 indicates rR and rf in the same coordinate system at two different magnifications of

the axes. One can clearly see that the two variables are completely independent

from each other and no relationship is possible to be formulated between them.

Therefore, it can be postulated that the coefficient of variation of the

rebound index (VR) could not be an acceptable estimate of the

coefficient of variation of concrete compressive strength (Vf) in

the proposed simplified way. If, however, the variation of the rebound index is

considered in a different way than the coefficient of variation of test

locations (e.g. by the adaptation of variograms to depict spatial variability

in geostatistics [46-47]) then the rebound hammer test may be a suitable tool

for the estimation of the coefficient of variation of concrete compressive

strength (Vf) in a practical situation. Further research is needed

in this field.

Fig. 20. Precision (normalized ranges) of the compressive strength test (rf,%) and rebound hammer test (rR,%) indicating two different magnifications of the axes of the coordinate system.

Fig. 20. Precision (normalized ranges) of the compressive strength test (rf,%) and rebound hammer test (rR,%) indicating two different magnifications of the axes of the coordinate system.

9. Conclusions

An extensive

statistical analysis of the variability of concrete rebound hardness parameters

has been made based on a large database of 60 years laboratory and in-situ

experience. The following conclusions can be drawn.

a) The average rebound index Rm(t) and the average compressive strength

of concrete fcm(t) – both

are time dependent material properties – can not be directly correlated to each

other as univariate functions; the relationship needs the introduction of the

series of multivariate functions, where the independent variables are the

degree of hydration, the type and amount of cement and aggregate, the

environmental conditions and the testing conditions.

b) An observational

reading error exists in the rebound hammer

test due to the design of the scale of the device. The observational

error can reach the magnitude of 20% in particular cases, but this error seems

to have negligible influence when rebound indices are averaged. It is not yet

demonstrated if the observational error may result bias of the rebound index

data. It is suggested that a simple development of the testing device may

eliminate the operator observational error: a scale of the index rider would be

needed that indicates both even and odd values rather than only even values as

it is the case for the original design.

c) Normality tests demonstrated that the precision of the original

N-type Schmidt hammer is superior to original L-type or Silver-Schmidt N-type

hammers for concrete. Lower precision of the L-type original Schmidt hammer and

of the Silver-Schmidt hammer is due to the lighter hammer masses impacting

within both devices and the sensitivity of the electro-optical recording

(Silver-Schmidt hammer).

d) The basic curve of EN 13791 for the rebound hammer test is not set

to an artificially lowest position for which always a positive shift could be

applied for the actual strength assessment. Basic curve of EN 13791 is

suggested to be reconsidered.

e) The within-test variation (repeatability) parameters of the rebound hammer

test have similar tendency to that of the within-test variation parameters of

concrete strength; i.e. no clear tendency is found in the standard deviation

over the average and a clear decreasing tendency can be observed in the

coefficient of variation by the increasing average. ACI 228.1R-03 Committee

Report implications contradict to these results, therefore, the within-test

variation statements in ACI 228.1R-03 are suggested to be reconsidered.

f) The probability distribution of the within-test standard deviation

of the rebound index as well as of the rebound index ranges of individual test

locations follow the Dagum distribution with strong positive skewness. ASTM C

805 implications can not fit to these findings, therefore the statements in

ASTM C 805 about the values of the standard deviation and the range of rebound

indices are suggested to be reconsidered.

g) For the rebound indices, the probability distribution of the

standardized ranges and that of the empirical studentized ranges are different

and their values are about to be equal only at their mean value levels. At 95%

probability level the difference is unacceptably high, therefore, the

application of Table 1 of ASTM C 670

for the rebound hammer test is suggested to be reconsidered.

h) The within-test coefficient of variation of the rebound index is

influenced by the w/c-ratio of the concrete, the age of the concrete, the

cement type used for the concrete, the testing conditions of the concrete, the

carbonation depth of the concrete and the impact energy of the rebound hammer.

i) The within-test coefficient of variation of the rebound index could

not be an acceptable estimate of the coefficient of variation of concrete

compressive strength, therefore, further research is needed to refine the

rebound hammer test to become a suitable tool for the estimation of the variability

of concrete compressive strength in a practical situation.

Authors hope

that the results of the statistical analyses introduced in present paper may add to, further

initiate and help the scientific progress of international scientific/technical

committees, directly RILEM TC ISC “Non destructive in situ strength assessment